Acrylic is a synthetic fabric originally developed as a wool alternative. It’s a popular material worldwide due to its ease of care, durability and comfort. This guide covers everything you need to know about acrylic fiber, including its origins, manufacturing process and uses.

Unlike cotton, linen, wool and silk, acrylic fabric is a manufactured fabric that doesn’t come from the natural world. It is woven or knitted with acrylic fibers.

These synthetic fibers derive from acrylonitrile, an organic compound that comes from petroleum or coal-based chemicals and various monomers. This makes acrylic fabric a fossil fuel-based fiber.

The fiber must contain at least 85% acrylonitrile monomer to be considered acrylic. The other copolymers are typically methyl methacrylate, vinyl acetate, methacrylic acid or another vinyl compound. These are added to improve mechanical properties and dyeability. A fiber less than 85% acrylonitrile monomer but greater than 35% is considered a modacrylic.

Acrylic fabric is warm, soft and lightweight. It is easy to wash and dries quickly. It’s also resistant to moisture, sunlight, chemicals, mildew and shrinkage. These qualities make it a popular choice for a range of items, from clothing and home decor to costumes and props.

The American DuPont Corporation — a firm that popularized polyester manufacturing and developed nylon — created acrylic fabric in the 1940s. DuPont was the same company that developed nylon and popularized polyester manufacturing. Consumers saw the invention of acrylic fibers as the next step in DuPont’s ascent to a leader in the global textile industry.

However, acrylic fabrics didn’t truly gain traction until the 1950s, when DuPont introduced it to the United States textile market. DuPont’s other synthetic textiles were believed to contribute to acrylic fiber’s slow mainstreaming. The firm had already replaced cotton with polyester and silk with nylon. This could have hindered customers’ interest in acrylic, which was intended to replace wool.

Acrylic became a widely used fabric for blankets, sweaters and many other items requiring frequent use, wearing and washing. Consumers eventually recognized its benefits, increasing its market share more over the decade. Many people believed synthetic fibers would eventually replace natural textiles.

Despite acrylic fabric’s rapidly growing popularity, consumers began to show concerns about its flammability — especially considering wool is one of the most flame-resistant natural fibers. While acrylic fibers are less flammable than cotton, they’re more flammable than wool and polyester.

Environmental groups started to push back against synthetic fabrics in the 1970s. Information about the material’s potential carcinogenic and toxic properties also swayed public opinion.

The DuPont Corporation is no longer the top producer of acrylic fiber. Companies in China, Indonesia, India and other ASEAN countries are now leaders in the acrylic fiber market. While acrylic fabric isn’t nearly as common in America today, it’s still prevalent in sweaters, gloves, athletic apparel and outdoor upholstery due to its excellent heat retention.

Here are the detailed stages of acrylic fiber manufacturing for a clearer idea of how the process works:

Traditionally, acrylic fibers were difficult to dye until the introduction of basic and cationic dyes. Cationic dyes are water-soluble, dissociating into colored cations and forming salts. They create strong bonds, providing optimal fade resistance.

Today, cationic dyes are frequently used for dyeing acrylics and modacrylics. Manufacturers typically apply these dyes in a batch process with stock, skein and package dyeing.

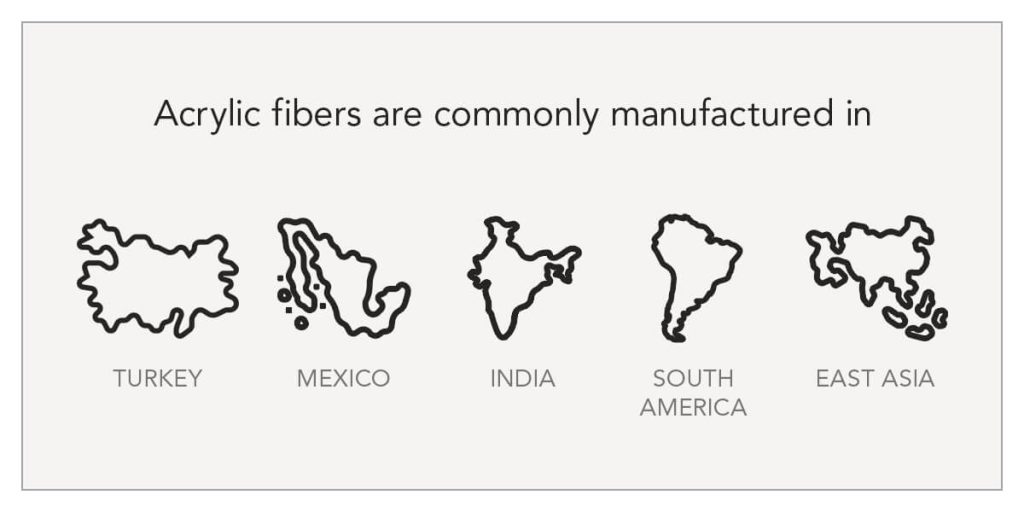

Acrylic fibers are commonly manufactured in Turkey, Mexico, India, South America and East Asia. However, China is the top acrylic fabric producer in the world. The country is responsible for over 30% of global acrylic fiber production and has the largest acrylic clothing market. India is projected to account for a sizeable share of the worldwide acrylic fiber market, as well.

Because acrylic fabric shares similar properties to wool, it can be used for many of the same applications. Acrylic fibers are present in many things we use daily — often in items we least expect. Here are some common uses of acrylic fabric.

Textile product manufacturers use acrylic fibers for various cold-weather clothing, including:

Acrylic fabric is one of the world’s least breathable textiles, making it ideal for heat-retention applications. For this reason, it’s commonly used to manufacture athletic wear like hoodies, tracksuits and pants. Manufacturers even use acrylic fabric for some protective equipment and clothing due to its durability and warmth.

Acrylic fabrics are in an array of home furnishings, including:

Manufacturers can create acrylic fabric resembling fur. This can be useful for various costumes and props. Acrylic fabric can also be found in wigs, hair extensions and hair brushes.

Acrylic fiber is commonly used in carbon fiber. Carbon fiber is a popular material for many industrial applications, such as aircraft and automotive parts, fishing rods, bicycle frames and more.

Acrylic fibers have a high carbon concentration of 67.9%, making them a suitable precursor for carbon fiber production. Aside from carbon fiber, however, acrylic fiber doesn’t have many industrial uses due to its flammability.

Knitting is one of the most common applications of acrylic fiber. Though some knitters prefer wool for their projects, new knitters often start with acrylic yarns for low-effort, inexpensive projects. Acrylic’s affordability and impressive color retention make it a staple in the knitting market.

Swavelle Group is committed to providing clients with exceptional designs and service. As a leader in the textile industry, we can work with you to create beautiful, durable custom fabrics for your customers. We domestically produce a wide range of products for numerous markets, including outdoor, contract, residential and RV.

Our team understands that each client has unique needs and applications, and we devote one-on-one care and attention to every project. Besides ensuring microbe- and weather-resistant textiles, we also prioritize sustainable products and manufacturing to mitigate our environmental impact.

Choose Swavelle Group for expertly curated decorative fabrics and quick turnaround times. Contact us today to learn more about our fabric and textile products.